The Decision to Develop Our Own Battery Pack

When we first started developing the N1-S, NUEN MOTO considered the easiest route: importing complete battery packs from China. This option was cheaper, more convenient, and, crucially, readily available. But choosing the easy path meant the N1-S would never truly become the electric motorcycle we envisioned.

Our R&D team also sought out and collaborated with domestic battery suppliers. However, while Vietnam's battery industry is booming, most readily available packs on the market are designed for general electric vehicles, operating at low to medium speeds under ideal conditions. For an electric motorcycle like the N1-S – built for strong acceleration, long rides, and operation in scorching sun or heavy rain – those packs simply wouldn't cut it.

To give you an idea: many current batteries can only handle light rain, often overheating or experiencing "thermal shock." Imagine riding through an unexpected downpour in Saigon during rush hour or embarking on a long tour – the risks for the rider would be immense.

Then there were the design demands; we needed a custom-fit solution for the N1-S's specific requirements.

After much research and deliberation, NUEN MOTO decided to develop our own battery pack. This allowed us to control quality, reduce dependence on external suppliers, and ensure the performance, safety, and aesthetics we desired.

The Battery Pack's Design Brief

To design a suitable battery pack, our R&D team meticulously broke down every issue and outlined the most specific details possible to guide the next steps.

A. Ensuring Vehicle Performance

- Deliver strong and stable current for instantaneous acceleration and high top speeds. For example, when a rider needs to quickly overtake on a highway or accelerate from a traffic light, the battery needs to deliver immediate power without delay.

- Optimize weight: make it as light as possible while still holding enough energy for each charge, allowing the bike to travel long distances without being too heavy. For an average trip from Ho Chi Minh City to Vung Tau (around 100km), the battery needed to support a round trip on a single charge.

B. Ensuring Durability & Safety in Tropical Climates

- Excellent water resistance: Given Vietnam's climate and vehicle usage intensity, the battery pack not only needed to be water-resistant but also capable of withstanding submerged conditions – a common occurrence during rainy seasons and high tides in Vietnam.

- Impact and vibration resistance: ensure the battery isn't damaged when riding over potholes or on steep mountain roads, like those in Bảo Lộc, Đà Lạt, or the Northwest.

- Absolute safety: prevent the risk of fire, explosion, electrical leakage, overcurrent, and short circuits – even in scorching conditions that can reach 40-50°C during summer afternoons.

- Meet, or even exceed, the registration standards set by the Vietnam Register. Everything would be pointless if the vehicle couldn't meet the criteria for circulation.

C. Production Suitability

- Reasonable cost: avoid pushing the vehicle's price too high for Vietnamese consumers. For instance, a battery for a mass-market electric vehicle shouldn't account for more than 50% of the total vehicle cost.

- Easy to upgrade and adjust as new cell technology, BMS (Battery Management System), or materials emerge.

- Compatibility with domestic production capabilities: from casing manufacturing to assembly – to control the supply chain, warranty, and after-sales service, avoiding reliance on imported goods. This is especially crucial given the volatile global trade landscape due to trade wars between major economies.

Solving the N1-S Battery Challenge

Embarking on the N1-S battery project was a challenging journey, starting with demands that seemed a bit "greedy." The first CAD drawing focused purely on performance, resulting in an incredibly powerful 12kWh pack. This would have given the N1-S "monster" acceleration and top speed. However, the range would be significantly shorter, the bike quite heavy, and the price would skyrocket. So, the question became: "What do most users truly need, how fast is fast enough, and how far is far enough?"

Balancing Speed and Range

In reality, most N1-S users primarily ride in urban areas, so hitting speeds above 80km/h is rare, let alone 120-130km/h. However, with the initial goal of a high-performance electric motorcycle, and occasionally using the bike for longer tours, high-speed capability was still necessary. While this would slightly impact the range per charge, around 200km per charge was deemed reasonable, allowing riders to stop, rest, and recharge if needed.

The Modular Battery Solution

After many rounds of testing and simulations, the R&D team made a crucial decision: not only reduce the capacity but also switch to a two-module, 4kWh battery configuration. The total capacity remained large but became more compact, optimizing mass production, simplifying layout, and making maintenance and removal easier in the future.

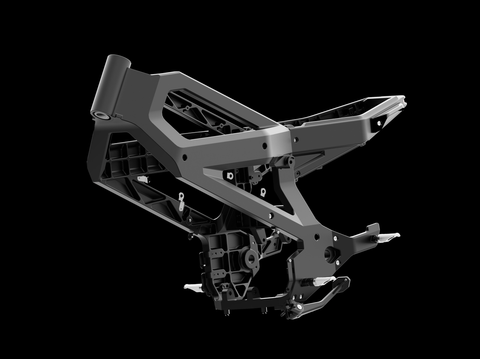

Bringing the Battery Pack to Life

The next step was the prototyping phase. Our internal engineers filtered through over 10 types of battery cells from domestic and international suppliers to select the most suitable one. The battery frame was constructed from powder-coated steel, and copper busbars were CNC-cut to optimize electrical pathways. The outer protective casing also received an aluminum layer for heat reduction and impact resistance.

Smart Battery Management System & 5-Layer Safety Standard

Once the cell type and optimal battery capacity were finalized, NUEN MOTO immediately partnered to develop a custom Battery Management System (BMS) tailored to the bike's battery system. This is the "brain" that controls energy flow, ensuring efficient operation, good performance, and safety. To enhance protection, we also implemented a 5-layer safety standard for the entire battery pack.

- Thermal Protection: Ensures safety when the battery overheats. The battery pack is protected by special heat-resistant materials, while generated heat is quickly dissipated through the external aluminum casing and optimized design for air cooling. Temperature sensors continuously monitor and adjust.

- Mechanical Protection: Individual battery cells are isolated and placed within a robust alloy casing, circuit protection devices are external, and the entire assembly is enclosed by a premium aluminum shell. This design effectively resists shock and impact and meets IP67 water resistance standards. The N1-S battery pack also features a pressure relief valve to maintain stable pressure under extreme operating conditions.

- Electrical Protection: Connectors and wires are designed to withstand high charge and discharge currents, with a compact, impact-resistant structure that adheres to strict industry standards. The system is equipped with an automatic cut-off when fully charged and only allows charging when safe conditions (battery temperature, charging current) are met, preventing overcharging.

- Electronic & Software Protection: The electronic components and battery protection circuits are controlled and managed by software with top-tier safety standards. This software continuously monitors battery status, detecting and addressing anomalies.

- Sensor Protection: Advanced sensors like pressure and temperature sensors operate continuously to provide accurate data on battery status, enabling the BMS to make timely decisions to maintain optimal safety and performance.

This means that from the smallest cell to the entire battery pack, everything is strictly protected to minimize all risks. Furthermore, the battery pack was designed to meet CE standards for the European market – stringent requirements that align with our goal of exporting bikes to demanding markets.

Flexible Charging Solution

Throughout this process, NUEN MOTO also recognized the limited charging infrastructure in Vietnam, even in major cities. Our R&D team integrated an onboard charger adapter. This allows riders to charge the bike with a simple cable, using both household 220V AC power and fast charging at compatible DC fast charge stations. This solution provides maximum simplicity and convenience for N1-S owners.

The entire battery pack takes less than 4 hours to fully charge using 220V electricity and just 1 hour with a dedicated fast charger.

The Final Tests

After assembly, we began the final product testing:

- Water resistance testing: Ensuring the battery functions well in all weather conditions and even in submerged environments.

- Impact simulation: Assessing the battery pack's durability and safety during collisions.

- High-intensity road tests: Continuously riding the bike on a demanding track, under scorching 38–40°C midday summer sun, to check operating temperatures.

Each testing round revealed more areas for improvement – from reinforcing contact points to designing additional drainage channels. Sometimes, the "experimental" battery pack overheated during fast charging – prompting the engineering team to optimize the cooling system and select more suitable cell types... Step by step, changes were made to perfect the battery pack.

In Conclusion

Looking back at the journey of creating the N1-S battery pack, we understand we chose a path that was far from easy. The initially "ambitious" requirements coupled with limited initial conditions pushed our R&D team to constantly research and experiment, embodying the spirit of "when things are tough, you get creative."

From balancing performance and range to deciding on a dual-module battery, developing a smart Battery Management System (BMS), and implementing a 5-layer safety standard, every step demanded immense time and effort from the R&D team. There were moments when we thought we were stuck, like when the test battery overheated, or when issues constantly arose during rigorous testing. Sometimes, we'd even stumble upon what we jokingly called "hidden features" that kept the whole team constantly on their toes.

The NUEN MOTO team didn't just create a battery pack; we breathed life into it, transforming it into a technologically advanced, durable, and absolutely safe "heart" for the N1-S. This isn't just the result of dry calculations or advanced technology, but the resilience, creativity, and adaptability of the NUEN MOTO team. We're proud to have turned the "craziest" demands into reality, offering you a truly distinct experience.

What aspects of NUEN MOTO's battery development process do you find most impressive or surprising?

For the N1-S, robustness and security are ensured by the thermal, mechanical, electrical protection and IP67 sealing.

For the N1-S, robustness and security are ensured by the thermal, mechanical, electrical protection and IP67 sealing.